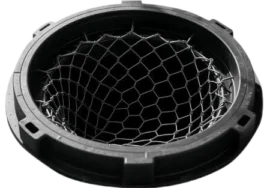

Is the Resin Manhole Cover Durable? A Complete Breakdown

When it comes to selecting the right manhole cover for infrastructure, one of the most common questions asked is: “Is the resin manhole cover durable?” While traditional ductile iron manhole covers are known for their superior strength, the rise of polymer composite materials has reshaped the conversation about durability, performance, and cost-efficiency. In this article, we’ll explore the durability, load-bearing capacity, and overall value of resin manhole covers, helping you understand whether they are the right choice for your project.

1. The Evolution of Manhole Cover Materials

Historically, cast iron and ductile iron have been the go-to materials for manhole covers due to their high compressive strength and load-bearing capabilities. However, with advances in material science and increased demand for sustainable, cost-effective, and lightweight alternatives, resin-based (polymer composite) manhole covers have rapidly gained popularity.

Polymer resin manhole covers are a relatively new innovation, engineered for automated production and designed to meet modern requirements such as anti-theft, corrosion resistance, light weight, and aesthetic customization. Though they started with a smaller market share, their adoption is growing fast across municipal, telecommunications, and utility sectors.

2. Load-Bearing Capacity: How Strong Are Resin Manhole Covers?

One of the primary performance metrics for any manhole cover is its load-bearing capacity. Ductile iron remains the leader in maximum strength, especially under extreme loads. However, modern resin composite covers have made significant strides, with some capable of bearing loads of over 50 tons—a level once thought achievable only by heavy metals.

To illustrate, a resin manhole cover rated at 10kN (kilonewtons) can bear approximately 1 ton of weight. Thanks to structural advancements, such as tank-bottom designs and the use of continuous fiber reinforcement, these covers can distribute pressure over a much larger area. This boosts their strength dramatically without adding weight.

Additionally, composite materials allow for the integration of glass fiber cloth and high-strength resins, resulting in a product that can endure repeated stress without cracking or fatigue. In fact, resin manhole covers can now meet or even exceed many national and international standards for load-bearing infrastructure products.

3. Durability and Service Life: Built to Last

So, are resin manhole covers truly durable? The answer is a resounding yes—and here’s why:

-

Material Science: Resin covers are built using high-performance resin, reinforced fiberglass, and proprietary chemical formulas that ensure deep resin penetration into the glass fibers. This bonding process creates a structurally integrated material with exceptional toughness and longevity.

-

Resistance to Environmental Stress: Resin manhole covers are immune to corrosion, UV degradation, and chemical exposure. Unlike metal, they do not rust or weaken over time when exposed to moisture, salt, or pollution, making them ideal for coastal, industrial, or high-moisture environments.

-

No Internal Damage from Cyclic Loads: Thanks to the elastic properties of the composite materials, repeated loading and unloading do not lead to microcracks or internal fatigue, which is often a concern in brittle or rigid materials.

In short, resin manhole covers offer a long service life with minimal maintenance—a key factor in reducing lifecycle costs for municipalities and developers.

4. Comparing Resin and Ductile Iron Manhole Covers

| Feature | Resin Manhole Cover | Ductile Iron Manhole Cover |

|---|---|---|

| Load-Bearing Capacity | Up to 50 tons (depending on design) | Higher; exceeds 50+ tons easily |

| Weight | Lightweight, easy to handle | Heavy; requires equipment for lifting |

| Durability | Very high; corrosion & weather resistant | Very high; but susceptible to rust/corrosion |

| Theft Risk | Very low; no resale value | High; often stolen for scrap metal value |

| Cost | More affordable | More expensive |

| Environmental Suitability | Excellent for corrosive or high-moisture areas | Requires coating or maintenance in such areas |

| Design Flexibility | Customizable colors, logos, textures | Limited customization |

While ductile iron may still be favored in high-load, high-traffic zones (e.g., highways), resin covers shine in urban streets, parks, sidewalks, telecom ducts, and utility zones, offering safety, cost savings, and ease of installation.

5. Anti-Theft Advantage: A Unique Edge

One major benefit of resin manhole covers is their built-in anti-theft protection. Unlike metal covers that can be sold as scrap, resin has no significant recycling or resale value, reducing the risk of theft. This alone saves significant costs for municipalities that otherwise frequently replace stolen covers.

Conclusion: Are Resin Manhole Covers Durable?

Absolutely. Thanks to advancements in composite technology, resin manhole covers offer excellent durability, competitive load-bearing capacity, and a range of additional benefits like anti-theft, corrosion resistance, and affordability.

While ductile iron remains unbeatable in certain heavy-duty scenarios, resin covers now represent a smart, modern alternative for many public and private infrastructure applications. Their long lifespan, resistance to harsh environments, and economic advantages make them a highly practical and future-ready solution.