Advantages of Composite Manhole Covers Vs Traditional covers

Smart, Safe, and Sustainable Solutions for Modern Infrastructure

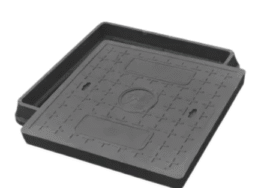

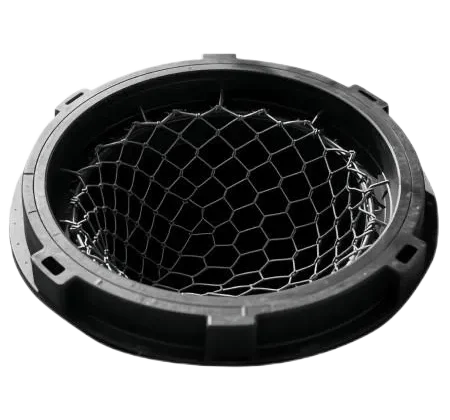

As cities grow and urban infrastructure evolves, the demand for smarter, safer, and more sustainable solutions becomes increasingly important. One such innovation is the composite manhole cover, a modern alternative to traditional cast iron or concrete covers. Made primarily from unsaturated polyester resin or polyurethane resin, and reinforced with steel mesh and fiber materials, composite covers offer a wide range of technical, environmental, and economic benefits.

Here’s a comprehensive look at how composite manhole covers outperform traditional ones in functionality, durability, safety, and environmental value:

1. Green Materials & Environmental Compliance

Composite manhole covers are manufactured using eco-friendly raw materials that comply with China’s national green building and environmental standards. These materials are not only non-toxic and recyclable, but also reduce the overall carbon footprint of urban infrastructure projects.

-

✅ Sustainable production process

-

✅ Lower resource consumption

-

✅ No harmful emissions during use or disposal

This makes composite covers an excellent fit for cities and municipalities pursuing low-carbon and eco-conscious development goals.

2. Superior Physical Performance

Formed under high temperature and ultra-high pressure through compression molding technology, composite manhole covers offer exceptional physical properties that rival and often exceed those of traditional metal or concrete covers.

-

🟢 High tensile strength and density

-

🟢 Excellent impact resistance

-

🟢 Superior load-bearing capacity with internal mesh reinforcement

These features allow composite covers to withstand heavy traffic loads, making them suitable for roadways, highways, sidewalks, and utility zones.

3. Corrosion Resistance and Weather Durability

Unlike metal covers that rust, corrode, or degrade when exposed to chemicals, salt, or moisture, composite covers are immune to corrosion. The resin matrix used in production resists:

-

⚗️ Acids

-

🧪 Alkalis

-

🧂 Saltwater

-

❄️ Extreme cold or heat

This allows composite manhole covers to be used in harsh environments, such as coastal regions, industrial zones, chemical plants, and high-humidity areas.

4. Lightweight Yet Strong

Despite their high strength, composite covers are much lighter than their iron or concrete counterparts. This has several operational benefits:

-

🚚 Easier to transport and install

-

🔧 Reduces labor costs

-

🦺 Improves worker safety

-

⏱️ Shortens installation time

A lightweight cover that still offers 50+ ton load capacity makes composite materials ideal for modern, high-efficiency construction projects.

5. Built-in Anti-Theft Design

One of the standout advantages of composite manhole covers is their extremely low theft risk. Traditional cast iron covers are often targeted for resale as scrap metal, leading to dangerous open holes and recurring replacement costs.

Composite covers, however:

-

Have minimal metal content (usually less than 10% of total weight)

-

Offer no significant resale value

-

Are visibly distinct, making them harder to sell or disguise

This feature is particularly valuable in public areas, where theft prevention translates into cost savings and public safety.

6. Rich Color Options & Long-Lasting Aesthetics

Thanks to their excellent plasticity and color retention, composite manhole covers can be customized in terms of:

-

🎨 Color variety (black, red, green, gray, etc.)

-

🖋️ Surface textures and branding (logos, symbols, text)

-

🧼 Glossy, smooth finish with a soft touch feel

Using through-material coloring technology, the color is baked into the composite itself—not painted—resulting in fade-resistant, durable finishes that maintain visual appeal for years, even under constant sun and wear.

7. Maintenance-Free and Long-Lasting

Composite manhole covers require no painting, rust-proofing, or frequent inspections, reducing long-term maintenance costs. Their resistance to UV rays, moisture, chemical exposure, and mechanical wear means they remain functional and attractive for decades.

Summary: Composite vs. Traditional Manhole Covers

| Feature | Composite Manhole Cover | Traditional Manhole Cover |

|---|---|---|

| Weight | Lightweight, easy to install | Very heavy, labor-intensive |

| Strength | High strength, mesh-reinforced | High (but heavier) |

| Corrosion Resistance | Excellent, rust-proof | Poor; requires coating or maintenance |

| Theft Risk | Low; minimal resale value | High; often stolen for scrap |

| Customization | High; color, branding, surface textures | Limited |

| Maintenance | Minimal; weather-resistant | Requires regular inspection and repair |

| Environmental Impact | Eco-friendly materials, recyclable | High carbon footprint |

| Cost-Effectiveness | Lower lifecycle cost | High upfront and replacement costs |

Conclusion: The Future of Urban Safety and Sustainability

Composite manhole covers represent a next-generation solution in infrastructure design. Their combination of strength, safety, sustainability, and cost-effectiveness makes them an excellent choice for cities, utility providers, and contractors looking to build modern, long-lasting public systems.

Whether for urban streets, highways, telecom ducts, or water networks, composite covers are transforming how we think about infrastructure durability and performance.

Choose composite. Choose innovation. Choose Baogai Group.